INTRODUCTION

ULTIMATE:TIME TO MAKE RECYCLED WATER A NEXT LEVEL RESOURCE

The ULTIMATE project will develop technologies to reuse industrial wastewater, creating economic value and increasing the sustainable use of resources.

9 Testing Sites Across Europe

Learn how different businesses in these industries are boosting their sustainability. Click on a case study below or keep scrolling for more details!

CS 1

Petrochemical Industry Reducing liquid waste to almost zero# 1 Tarragona, Spain

CLICK THE PLAY BUTTON AND SLIDE THE CURSOR

CS 2 New Prinsenland

HorticultureEfficient heating and watering in greenhouses# 2 Nieuw-Prinsenland, The Netherlands

Additionally, the project will demonstrate that wastewater from glasshouses can be recycled and reused in horticulture. Greenhouse operators hesitate to reuse their wastewater as it can contain plant pathogens. To remove these, a customised treatment plant will combine 3 different technologies. The system will also remove pesticides, which are used to protect crops like tomato from pests.

CS 3

Public Private PartnershipManaging high salinity# 3 Rosignano, Italy

CS 4

Juice ProductionAntioxidants from wastewater# 4 Nafplio, Greece

A new water purification plant is being developed, tailored to the sectors specific needs. It will recycle the wastewater generated during juice production and stimulate its reuse in the industry. Beyond that, the system will extract valuable compounds such as polyphenols, which can be added to fruit juices as antioxidants.

Go to the next slide to watch how the ULTIMATE engineers set up the plant!

CS 5

BreweryRecovering sludge for biogas generation# 5 Lleida, Spain

These bioreactors are furthermore part of a treatment train which produces fit-for-purpose water. This will enhance the industrial symbiosis between the Mahou brewery and the water management company Aqualia.

CS 6 Israel

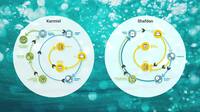

Olive MillsDealing with seasonal wastewater shock loads# 6 Karmiel & Shafdan, Israel

In addition, a new anaerobic system for pretreatment of wastewater is installed at Israel’s largest wastewater treatment plant in Shafdan. It will make the plant more flexible to treating wastewater when its composition changes; i.e. effluents from olive mills, dairy farms and domestic wastewater.

Check out how new technologies will recycle wastewater and recover energy and materials in the following animations.

CS 7

Wiskey DistilleryUtilising the potential of distillery wastewater# 7 Tain, Scotland, UK

The existing wastewater treatment system (anaerobic membrane bioreactor) is equipped with so-called ammonia stripping and reverse osmosis units. This will recycle water to meet the quality requirements for internal cleaning and recover nutrients for fertilisation of barley, one of whiskey`s ingredients.

Learn more in the following video.

CS 8 St. Maurice L´Exil

Chemical IncineratorUsing flue gas washing water as a resource# 8 St. Maurice I´Exil, France

The ULTIMATE partners determine the potential to recover heat and sulphur from water which was used to wash flue gases. This will reduce the energy consumption of the water treatment plant on site. It will also decrease the formation of waste gypsum and sodium sulphate.

CS 9

Wastewater Treatment PlantPushing from good to better# 9 Kalundborg, Denmark

In addition, a joint control system for two wastewater treatment plants, an industrial and a municipal one, is being established to save chemicals and energy.

A concept study investigates promising technologies for the recovery and internal use of sulphur and acetic acid.

ULTIMATE:

ULTIMATE:

9 Testing Sites Across Europe

9 Testing Sites Across Europe

Reducing liquid waste to almost zero

Reducing liquid waste to almost zero

Efficient heating and watering in greenhouses

Efficient heating and watering in greenhouses

Managing high salinity

Managing high salinity

Antioxidants from wastewater

Antioxidants from wastewater

Recovering sludge for biogas generation

Recovering sludge for biogas generation

Dealing with seasonal wastewater shock loads

Dealing with seasonal wastewater shock loads

Utilising the potential of distillery wastewater

Utilising the potential of distillery wastewater

Using flue gas washing water as a resource

Using flue gas washing water as a resource

Pushing from good to better

Pushing from good to better

ULTIMATE

ULTIMATE