INTRO

Lasertechnology: From bio-medical application to high-precision machines12 ways nano-patterns can make great improvements

Regarded as a side effect of laser technology for decades, they are increasingly in the spotlight:

Laser-induced periodic surface structures (LIPSS)

These microscopic patterns can form on the surface of almost any material when irradiating it with ultra-short laser pulses.

LIPSS possess great application potential in many industries including the biomedical and energy sectors. Keep scrolling to learn more about 12 uses of LIPSS you had never imagined!

10 uses of LIPSS

#1 LIPSS for anti-wettingLotus effect mimickry

These structures can be generated through ultra-short laser pulses to mimick the anti-wetting properties on glass or metallic surfaces for self-cleaning windows and windshields or to reduce corrosion and stiction in machinery.

#2 LIPSS for anti-icing surfacesProper functioning of aircraft at freezing temperatures

#3 LIPSS to create anti-fingerprint surfacesSpotless touch application

For this to work, so-called amphiphobic surfaces must be created, for instance, through LIPSS. Such surfaces then repel both water and skin oil, the two main components of fingerprints.

#4 LIPSS for improved blood oxygenationPrevention of clogging in heart-lung machines

#5 Anti-bacterial surfacesLIPSS to repel bacteria

In practice, it is challenging to get all the conditions just right for that to happen and not the opposite. However, initial research shows the potential of ultra-short pulsed laser technology to create antibacterial surfaces.

#6 LIPSS on medical implantsFaster recovery and extended implant life

The multi-laser beam module developed by Laser4surf creates functionalised surfaces to facilitate exactly that:

Quicker and better attachment of cell tissue to the implant for faster recovery.

#7 LIPSS in Li-ion batteriesExtending the lifetime of Li-ion batteries

One copper coated, the anode, and one aluminium coated, the cathode. They store the lithium ions and release them during battery operation for electricity to flow.

Additionally, laser engraving circumvents expensive carbon coating methods and harmful etching processes, which are applied during the manufacturing of current collectors.

#8 Light bulbs and LEDsLIPSS to brighten up lamps

Scientists have also demonstrated that LIPSS can increase the power output of Gallium-nitride-based LEDs by 30%; which are diodes used in displays and traffic lights.

#9 LIPSS for next generation solar cellsHarnessing solar energy more efficiently

Light incoupling: LIPSS ensure more light enters the module.

Light trapping: The captured light stays in the cell for longer.

#10 LIPSS for structural colourationCreation of vibrant colours

Structural colour on a stainless steel surface.

The colours are created by periodic, microscopic patterns engraved on the surface through laser texturing. By varying the period of the nano-structures, the textured surface reflects different wavelengths and produces different colours. This can be achieved with LIPSS too.

The colours change in hue with the viewing angle when the spacing between the ripples is constant (a) and they appear homogenous when ripples vary in period spacing (b). However, when mixing different variable period spacings, light is reflected non-specifically and appears white (c).

#11 LIPSS for anti-reflectionEssential parts of PCR machines: Optoelectronic devices

Qualitative anti-reflective surfaces ensure better transmission and contrast of the light signal and hence play an important role for the performance of optoelectronic devices.

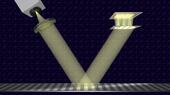

#12 LIPSS in linear encodersTuning measurement accuracy

Scientists from the Laser4surf project introduce LIPSS onto the encoder's scale to obtain a finer grid. Compared to conventional devices, the light signal reflected onto the detector is sharper and higher in contrast.

This enhances the encoder's precision and makes the device less sensitive to disturbances, like vibrations.

The all-in-one machineThe Laser4surf prototype

All these innovative applications require different processing parameters to generate the desired, unique pattern. Additionally, texturing surfaces at sub-micron level is time-consuming and expensive. Laser4Surf seeks to overcome this and bring laser texturing to mass production. The researchers and engineers will design a single machine to carry out all the necessary production steps: defining the required parameters, processing the surface and inspecting the product.

12 ways nano-patterns can make great improvements

12 ways nano-patterns can make great improvements

VIDEO Laserstructuring explained

VIDEO Laserstructuring explained

Lotus effect mimickry

Lotus effect mimickry

Proper functioning of aircraft at freezing temperatures

Proper functioning of aircraft at freezing temperatures

Spotless touch application

Spotless touch application

Prevention of clogging in heart-lung machines

Prevention of clogging in heart-lung machines

LIPSS to repel bacteria

LIPSS to repel bacteria

Faster recovery and extended implant life

Faster recovery and extended implant life

Extending the lifetime of Li-ion batteries

Extending the lifetime of Li-ion batteries

LIPSS to brighten up lamps

LIPSS to brighten up lamps

Harnessing solar energy more efficiently

Harnessing solar energy more efficiently

Creation of vibrant colours

Creation of vibrant colours

Essential parts of PCR machines: Optoelectronic devices

Essential parts of PCR machines: Optoelectronic devices

Tuning measurement accuracy

Tuning measurement accuracy

The Laser4surf prototype

The Laser4surf prototype

Laser4surf

Laser4surf